OUR TECHNOLOGY

All-in-One Solutions

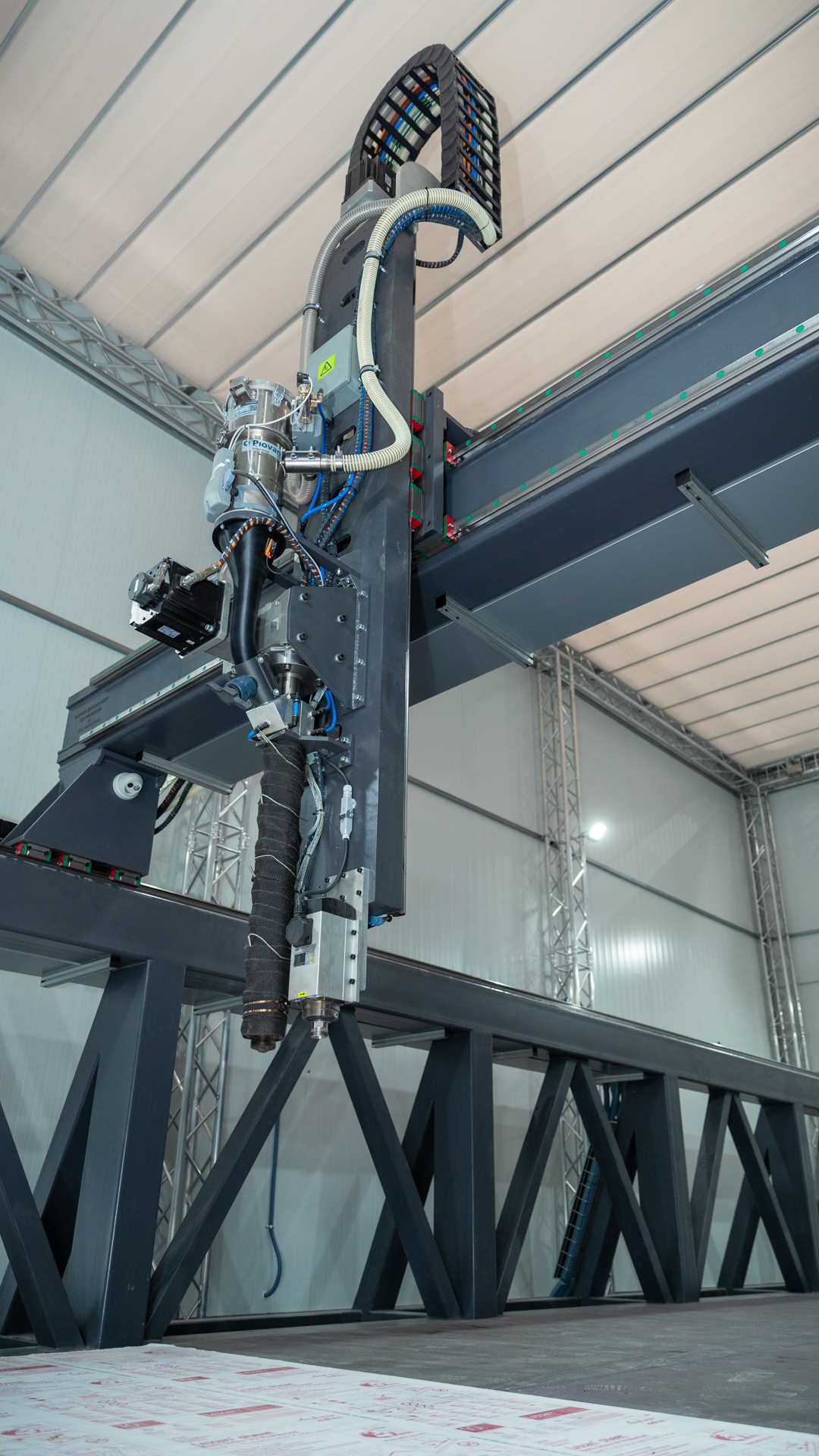

Plotter for 3D printing with dimensions 10 x 3 x 2 m that can print any type of thermoplastic polymer, two Laser Tracker measurement equipment with measurement precisions of +/-0.01 mm.

We provide our clients with personalized value-added solutions in:

3D design of complex airfoils and reverse engineering.

Technology, processes and systems involved in manufacturing. (CAD/CAM)

Resin Transfer Molding (RTM) and Infusion

Carbon and glass fiber Prepeg system.

High temperature epoxy resin system and BMI type resins, cyanoester for very high temperature applications.

Vacuum Assisted Resin Infusion Molding (VARIM)

Automated Tape and Fiber Laying Machine (ATL).

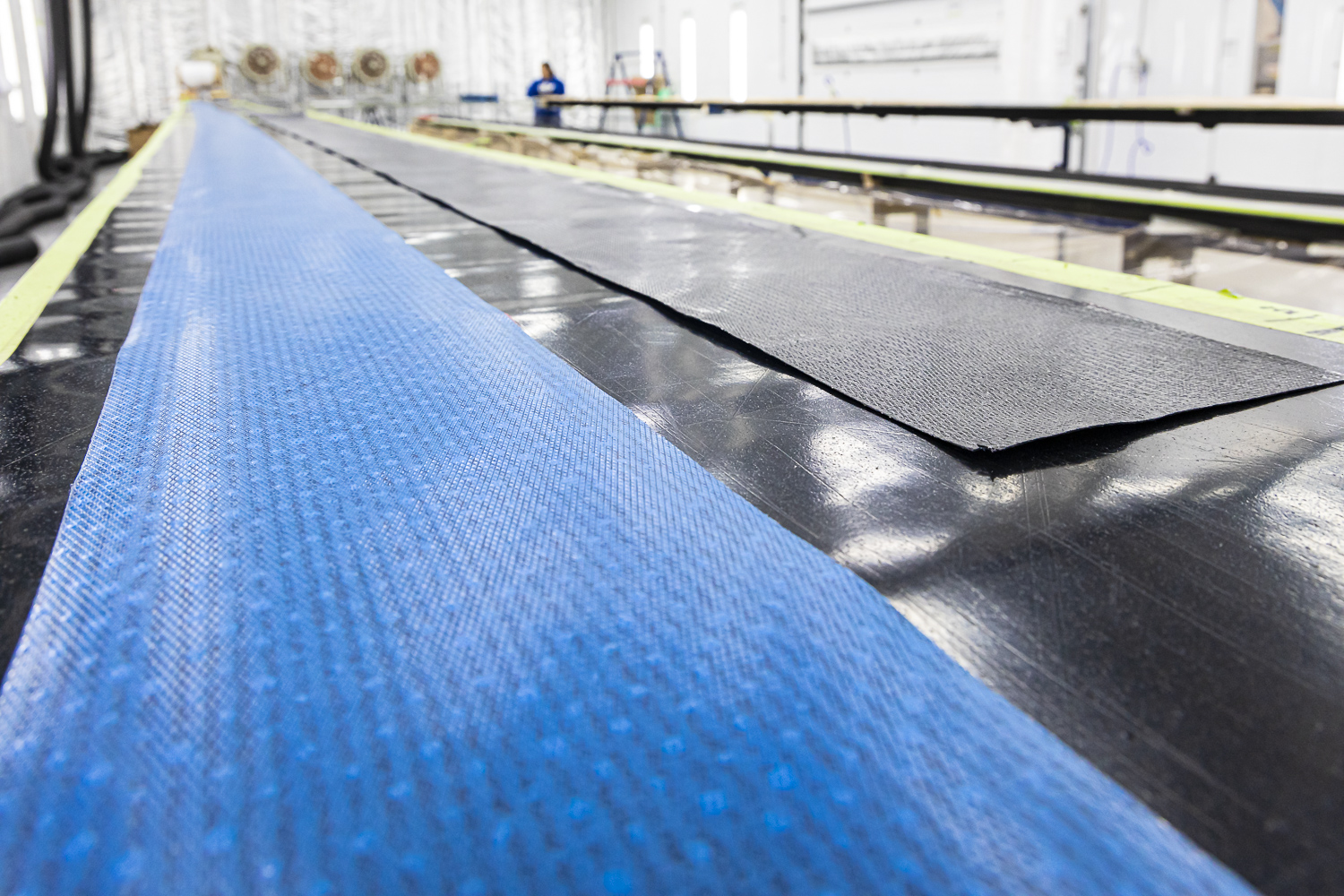

2 Dry and prepreg fiber cutting machines.

Large size plotter for cutting carbon, mylar, kevlar and other fabrics.

Hot wire machine to cut the EPS foam blocks.

Large ovens with curing control SCADA system.

Molds heated by embedded hot wire.

Hydraulic press of 80 T and 300ºC of 1 x 1 m

Analysis by finite elements. (ANSYS) Mechanical module and composite materials.

FARO Laser tracker & Scanner for reverse engineering. Laser projectors for the positioning of reinforcements.

HOW WE DO IT

With your requirements

And more than 20 years of experience in the sector, the SRG team has evolved from a vertical structure to the creation of teams capable of carrying out their project in an autonomous way.

Call Us

(+34) 968 505 096

Email Us

sinergia@sinergiarg.com

- Extensive knowledge of national and international markets.

- Excellent knowledge of composite materials.

- Understanding of business and operational processes.

- Highly qualified and committed staff.

- Intensive use of new techniques, procedures and machines.

- Customer and results orientation

- Proactive, assertive and comprehensive approach.

- Entrepreneurial spirit and teamwork.

- Adaptability and flexibility.

- Decision making

Our Commitment

We Will Always Provide The Best Technology For your Project

CNC I

X=23.8m Y=6.5m Z=3.2m | Precisión +/- 0.5mm

CNC II

X=26m Y=8.5m Z=4.0m | Precisión +/- 0.5mm

CNC III

X=6m Y=2.2m Z=0.8m | Precisión +/- 0.5mm

We Will Always Provide The Best Technology + 20 years of experience

Our mission is to provide our customers with engineering solutions through our knowledge of composite materials and materials engineering, together with our process competencies.

PRE-PREG CABIN

Having the latest technology and equipment for the manufacture of high standard projects, as far as product quality is concerned, is our sign of differentiation.

It is a clean room, free of dust and external contaminating agents, where environmental conditions are controlled: humidity and temperature.

We work under specific conditions with the latest technology materials: pre-impregnated carbon.

The booth facilities are air-conditioned to perform oven and cooling functions, thanks to a powerful extraction and ventilation system.